Product Description

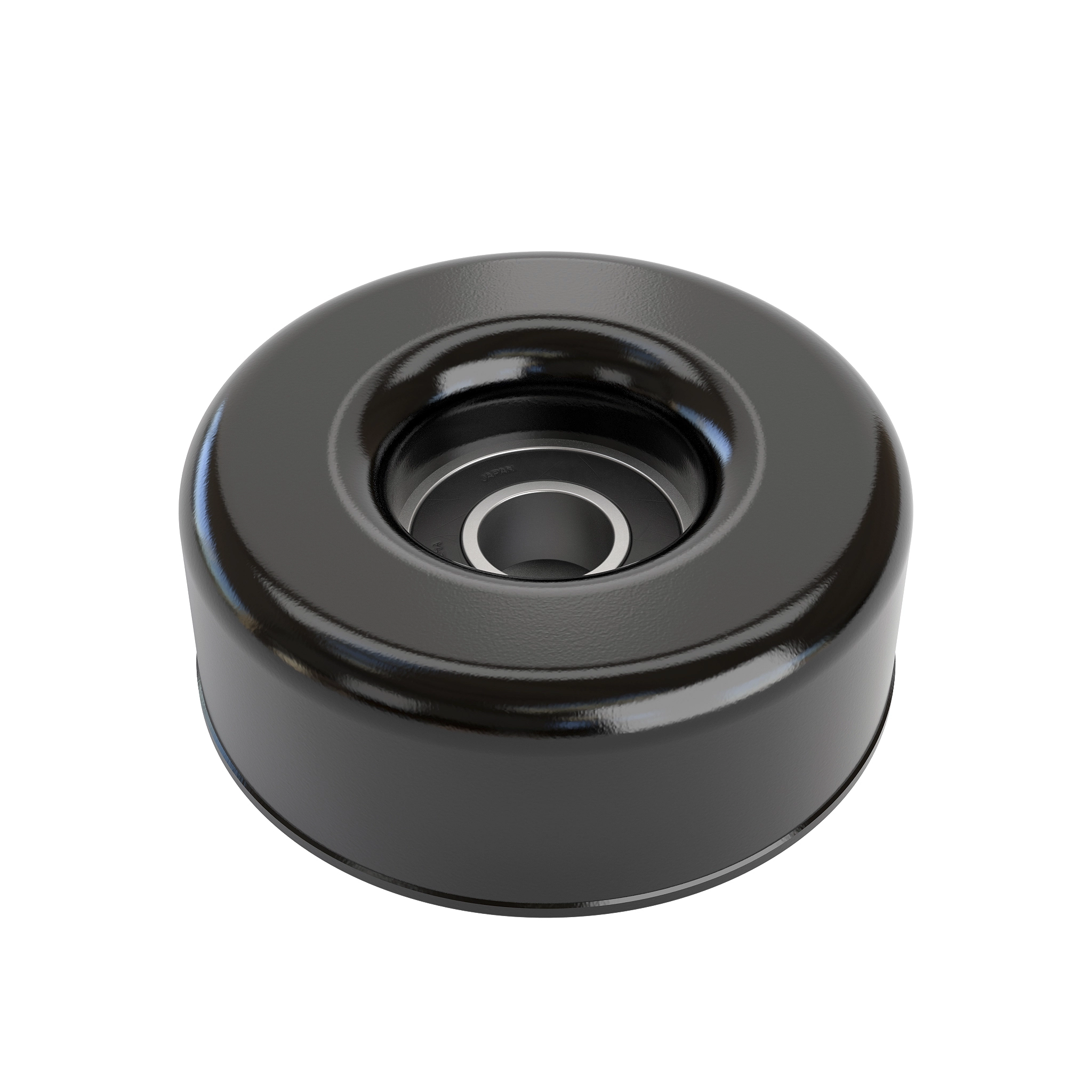

Nta855 Diesel Engine Water Pump Idler Pulley 306 Ar45189

| Product Name: | NTA855 Engine Water Pump idler pulley 3064919 305 0571 AR45189 |

| Engine Model: | NTA855 |

| Part/No.: | 3064919 305 0571 AR45189 |

| MOQ: | 1PC |

357109 Pump, Water & Idler

1 182706 Screw, Hexagon Head Cap

357108 Pump, Water

2 S 911 B Plug, Pipe

3 S 16255 Ring, Retaining

4 196844 Spacer, Bearing

5 3 Plug, Pipe

7 3571861 Pulley, Water Pump

8 4026537 Seal, Rectangular Ring

9 357163 Body, Water Pump

10 305 0571 Shaft, Water Pump

11 3 0571 46 Bearing, Ball

3064919 Pulley, Idler

3 S 16255 Ring, Retaining

12 S 201 Nut, Heavy Hexagon

13 S 965 E Plug, Pipe

14 213082 Washer, Plain

15 215397 Pulley, Idler

16 305 0571 Spacer, Mounting

17 305 0571 Shaft, Idler

18 3 0571 46 Bearing, Ball

3571832 Mtg, Water Pump

19 3012468 Screw, Captive Washer Cap

20 3012469 Screw, Captive Washer Cap

21 3076522 Gasket, Water Pump

22 217638 Belt, V Ribbed

| 40 0571 2 | SEAL,O RING |

| 4078944 | SEAL,O RING |

| 211657 | CONNECTION,AIR CROSSOVER |

| 4096366 | TUBE,LUB OIL SUPPLY |

| 3679445 | SPACER,MOUNTING |

| 3925402 | SCREW,HEX FLANGE HEAD CAP |

| 3897201 | NOZZLE,INJECTOR |

| C625719180 | HOSE,MOLDED |

| ST1266 | DRIVER, CYLINDER LINER |

| 106221 | CLIP |

| 3924628 | TUBE,FUEL SUPPLY |

| 357137 | CLAMP,INJECTOR |

| 3628927 | HOSE,FLEXIBLE |

| 4571520 | QSK50 CM850 IND CR WIRING |

| 357132 | COUPLING,ELBOW HOSE |

| 3 0571 15 | PLUG,RETAINER |

| 3571361 | BRACKET,TURBOCHARGER |

| AM12072 | HOSE,FLEXIBLE |

| 3006744 | SLEEVE,WEAR |

| 397 0571 | TANK,EXPANSION |

| 4955605 | TURBOCHARGER,HX40W |

| 3899753 | HOSE,FLEXIBLE |

| 3822765 | ASSY, INJ PLUNGER EXT |

| 3899970 | UNION,MALE |

| 3978056 | MODULE,ETR INTERFACE |

| 3800604 | KIT,FUEL SOLENOID |

| 3 0571 34 | TUBE,BREATHER |

| 3330942 | SEAL,O RING |

| 3013305 | TUBE,WATER TRANSFER |

| ST75302 | SOCKET, SCREWDRIVER |

| 3916065 | TUBE,SEA WATER PUMP |

| 25711 | ADAPTER,EXHAUST OUTLET |

| 3954918 | CONNECTION,WATER OUTLET |

| 357147 | PULLEY,ACCESSORY DRIVE |

| 5566 | GEAR,FLYWHEEL RING |

| 3571099 | SEAL,WATER PUMP |

| 4 0571 33 | SPACER,MOUNTING |

| 3963452 | HOSE,FLEXIBLE |

| 138797 | SPRING,FUEL PUMP TORQUE |

| 3379664 | INJECTOR PARTS, FLOW (04 |

| 212301 | SUPPORT,ENGINE |

| 3678737 | SEAL,O RING |

| 3633573 | TUBE,CPR WATER OUTLET |

| AM0601800SS | HOSE,FLEXIBLE |

| 3885823 | CLEANER,FUEL SYSTEM |

| 3905047 | TUBE,WATER TRANSFER |

| 3535215 | CLAMP,HOSE |

| S149A | SCREW,HEXAGON HEAD CAP |

| 4571194 | VALVE,FUEL SHUTOFF |

| 405717 | TUBE,WATER TRANSFER |

| 4 0571 70 | PULLEY,ACCESSORY DRIVE |

| 3349385 | HOSE,FLEXIBLE |

| 3157116 | TUBE,WATER OUTLET |

| 4985465 | ELBOW,TUBE CONNECTOR |

| 3635396 | TUBE,WATER BYPASS |

| 4964144 | MANIFOLD,FUEL |

| 3558717 | SUPPORT,AIR COMPRESSOR |

| 3376636 | ASSY, BUSH INSTL/REMOVAL |

| 3634656 | ELBOW,MALE ADAPTER |

| 4938949 | BEARING,CRANKSHAFT THRUST |

| 3974293 | PAN,OIL |

| 3966458 | HEAD,CYLINDER |

| 3945920 | SET,MAIN BEARING (030) |

| 3636045 | CONNECTION,AIR TRANSFER |

| 4065785 | O-RING |

| 3925618 | HARNESS,WIRING |

| 3375137 | TOOL, AFC FP ANEROID ADJ |

| 3666008 | 1991 C SERIES SHOP |

| 3179736 | HOSE,FLEXIBLE |

| 3251545 | TUBE,FUEL DRAIN |

| 4939408 | CONNECTION,EXHAUST OUTLET |

| 3637761 | HOSE,FLEXIBLE |

| 3034288 | HARNESS,WIRING |

| 3824703 | TOOL, ACC DR BUSHING R/I |

| 3637762 | HOSE,FLEXIBLE |

| 3823964 | KIT, RING GROOVE CHECK |

| 357112 | CLEANER,AIR |

| 4981096 | CONNECTOR,QCK DISCONNECT |

| 4893494 | GASKET,COVER PLATE |

| 4951843 | BRACE,AIR COMPRESSOR |

| 185139 | ADAPTER,INJECTOR PTD |

| C625716421 | CONNECTION,WATER OUTLET |

| 3375604 | SLEEVE, AFC BARREL PULLER |

| 3635078 | CONNECTION,WATER TRANSFER |

| 4571138 | ISF2.8 CM2220 WIRING DIA |

| 2896831 | TUBE,INJECTOR FUEL SUPPLY |

| 3929006 | INSERT,VALVE |

| 3958209 | PAN,OIL |

| 3965924 | SUPPORT,ALTERNATOR |

| 3017278 | HOSE,PLAIN |

| 4927649 | HOSE,FLEXIBLE |

| 4918342 | CABLE,ELECTRICAL |

| 3908402 | TUBE,WATER OUTLET |

| 3103077 | GASKET,EXH GAS RCN VALVE |

| 3971305 | HARNESS,WIRING |

| 3457162 | TUBE,AFTERCOOLER |

| 3632308 | HOSE,PLAIN |

| 357126 | HARNESS,WIRING |

| 3571292 | TUBE,LUB OIL SUPPLY |

| 3163571 | PIN,TIMING |

| 3685719 | SHAFT,IDLER |

| 3819789 | HOSE,FLEXIBLE |

| 395711 | GEAR,IDLER |

| 3635887 | BRACKET,TURBOCHARGER |

| 3947799 | VALVE,PRESSURE RELIEF |

| 457179 | BRACE,TUBE |

| 2896833 | TUBE,INJECTOR FUEL SUPPLY |

| 201705 | COVER,TOR CNV OIL COOLER |

| 4571585 | QSK19 CM850 PWR GEN WIRE |

| 3666206 | C8.3 NG T/SHOOTING&REPAIR |

| 3352546 | PAN,OIL |

| 175716 | XIHU (WEST LAKE) DIS.,VALVE SPRING |

| 153408 | COUPLING,PLAIN HOSE |

| 5255743 | TUBE,LUB OIL DRAIN |

| 315719 | SUPPORT,FRONT ENGINE |

| 3161582 | CLAMP,TUBE |

| 3003308 | LEVER,GOVERNOR |

| 3068573 | SUPPORT,FRONT ENGINE |

| 3201391 | ELBOW,MALE UNION |

| 3 0571 83 | ISOLATOR,VIBRATION |

| 3 0571 84 | ISOLATOR,VIBRATION |

| 3926969 | TUBE,AIR FUEL CONTROL |

| 405715 | NUT,LOCK |

| 3666256 | WARRANTY FAILURE CODEHEAV |

| 3571537 | SCREW,HEXAGON HEAD CAP |

| 4571375 | QSK23 T&R MANUAL |

| 3157195 | TUBE,WATER INLET |

| 3157139 | TUBE,WATER OUTLET |

| 3 0571 31 | ROD,PUSH |

| 3092970 | BELT,V RIBBED |

| 4927672 | BRACKET,WATER TUBE |

| 32571 | CONNECTION,AIR CROSSOVER |

| 3178289 | GASKET,AFTERCOOLER COVER |

| 3 0571 39 | RING,PISTON TURBO |

| 3892321 | SUPPORT,FAN |

| 3913326 | LEVER,NON-BREAKOVER |

| 496 0571 | ISB/ISD CM2150 SER.1-2 RU |

| 4960983 | SEV MAN ISL8.9 VOL 1/2 RU |

| 3571523 | COVER,GOVERNOR DRIVE |

| 3884342 | VTA28 GD PARTS |

| 3635398 | TUBE,WATER TRANSFER |

| 3163929 | CONNECTOR,ELC REPAIR |

| S147 | CAPSCREW |

| 3931997 | CONNECTION,AIR CROSSOVER |

HangZhou CHINAMFG Industry & Trade Co., Ltd.

Add:Haili Industry Park ,HangZhou Economic Development Zone ,ZheJiang ,China

Post Code:442013

engine /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 3064919 3050398 Ar45189 |

|---|---|

| Warranty: | 3064919 3050398 Ar45189 |

| Car Model: | 3064919 3050398 Ar45189 |

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do idler pulleys contribute to the functioning of HVAC and conveyor systems?

Idler pulleys play a crucial role in the functioning of HVAC (Heating, Ventilation, and Air Conditioning) and conveyor systems. Here’s a detailed explanation of how idler pulleys contribute to the operation of these systems:

HVAC Systems:

In HVAC systems, idler pulleys are primarily used for power transmission and belt tensioning. Here are the key ways in which idler pulleys contribute to the functioning of HVAC systems:

1. Belt Routing and Tensioning:

Idler pulleys guide and support the belts used in HVAC systems, ensuring proper routing and tensioning. They help keep the belts in alignment with the driving and driven pulleys, preventing slippage and ensuring efficient power transmission. Idler pulleys maintain the necessary tension in the belts, which is crucial for optimal HVAC system operation.

2. Load Distribution:

Idler pulleys assist in distributing the load evenly across the HVAC system. By supporting the movement of belts, they help distribute the load and minimize stress on individual components. Proper load distribution ensures balanced wear and tear, prolonging the lifespan of the system.

3. Noise and Vibration Reduction:

Idler pulleys contribute to reducing noise and vibration in HVAC systems. They help dampen vibrations caused by belt operation, resulting in quieter and smoother system performance. Reduced noise and vibration levels enhance the comfort and usability of the HVAC system.

4. System Efficiency:

Efficient idler pulley operation improves the overall efficiency of HVAC systems. Well-designed idler pulleys with low friction and proper tensioning minimize power losses, ensuring optimal energy consumption. By reducing inefficiencies and maximizing energy conservation, idler pulleys contribute to improved HVAC system performance.

Conveyor Systems:

In conveyor systems, idler pulleys are essential for belt support, tensioning, and guiding. Here’s how idler pulleys contribute to the functioning of conveyor systems:

1. Belt Support:

Idler pulleys provide support to the conveyor belt, preventing sagging and maintaining its shape. They are strategically positioned along the belt path to support the weight of the conveyed material, ensuring smooth and reliable transportation. Proper belt support is crucial for preventing belt damage and ensuring efficient material handling.

2. Tensioning:

Idler pulleys are used for belt tensioning in conveyor systems. They help maintain the appropriate tension in the conveyor belt, ensuring proper engagement with the drive pulley and preventing slippage. Proper belt tensioning is critical for efficient power transmission and preventing material spillage or jamming.

3. Belt Guiding and Tracking:

Idler pulleys guide and track the conveyor belt, ensuring it stays aligned and centered. They are designed with grooves or cylindrical surfaces that match the shape of the conveyor belt, providing guidance and preventing lateral movement. By maintaining proper belt tracking, idler pulleys minimize belt misalignment, reducing the risk of damage and improving overall conveyor system performance.

4. Load Distribution:

Idler pulleys contribute to even load distribution in conveyor systems. By supporting the belt and load, they help distribute the weight evenly across the system, minimizing stress on individual components. Proper load distribution ensures reliable and efficient operation, preventing premature wear and component failure.

5. System Reliability:

Reliable idler pulley operation is crucial for the overall reliability of conveyor systems. Idler pulleys that are correctly sized, well-maintained, and properly lubricated contribute to the smooth and continuous operation of the system. They help minimize downtime, reduce the risk of belt slippage or jamming, and ensure the efficient movement of materials.

Overall, idler pulleys are essential components for the functioning of HVAC and conveyor systems. Their role in belt routing, tensioning, load distribution, noise reduction, system efficiency, and reliability makes them integral to the smooth operation and performance of these systems.

How do idler pulleys impact the performance of automotive and industrial systems?

Idler pulleys play a crucial role in the performance of automotive and industrial systems. Here’s a detailed explanation of how idler pulleys impact the performance of these systems:

1. Belt Tension and Stability:

Idler pulleys help maintain proper belt tension in automotive and industrial systems. They guide and support the belts, ensuring they remain engaged with the pulleys and operate with the desired tension. Proper belt tension is crucial for efficient power transmission, preventing slippage, and maintaining stability in the system. Idler pulleys contribute to the overall reliability and performance of the system by ensuring consistent and reliable belt tension.

2. Belt Routing and Alignment:

Idler pulleys assist in routing and aligning belts in automotive and industrial systems. They are strategically positioned to guide the belts along the desired path, ensuring they are properly aligned with other pulleys and components. Correct belt routing and alignment minimize wear, reduce noise, and optimize power transfer efficiency. Idler pulleys help maintain the desired belt alignment, which is crucial for the smooth operation and longevity of the system.

3. Load Distribution:

Idler pulleys contribute to the even distribution of loads in automotive and industrial systems. By guiding the belts and supporting their movement, idler pulleys help distribute the load evenly across the system. This helps prevent excessive stress on specific components and promotes balanced wear and tear. Proper load distribution enhances the overall performance, reliability, and lifespan of the system.

4. Noise and Vibration Reduction:

Idler pulleys play a role in reducing noise and vibration in automotive and industrial systems. They help dampen vibrations caused by belt operation, minimizing noise and improving the comfort and user experience. By reducing noise and vibration levels, idler pulleys contribute to a quieter and smoother operation of the system.

5. System Efficiency and Energy Conservation:

Efficient idler pulley operation positively impacts the overall efficiency of automotive and industrial systems. Well-designed idler pulleys with low friction and proper bearing selection minimize power losses and maximize energy conservation. Idler pulleys that operate smoothly and efficiently contribute to improved system performance and reduced energy consumption.

6. Component Protection:

Idler pulleys help protect other system components, such as belts, by ensuring proper tension, alignment, and load distribution. By maintaining optimal belt operation, idler pulleys prevent excessive wear, slippage, and premature failure of belts and other related components. This protection enhances the reliability and longevity of the entire system.

7. System Reliability and Durability:

The proper functioning of idler pulleys is crucial for the overall reliability and durability of automotive and industrial systems. Idler pulleys that are correctly sized, well-maintained, and appropriately lubricated contribute to the smooth and continuous operation of the system. They help minimize downtime, reduce the risk of component failure, and ensure the system can perform its intended functions reliably over an extended period.

Overall, idler pulleys have a significant impact on the performance, efficiency, reliability, and durability of automotive and industrial systems. Their role in maintaining belt tension, routing and alignment, load distribution, noise reduction, system efficiency, component protection, and overall system reliability makes them essential components in these applications.

What is an idler pulley, and what is its role in mechanical systems?

An idler pulley is a specific type of pulley that is used in mechanical systems. Here’s a detailed explanation of what an idler pulley is and its role in mechanical systems:

Definition:

An idler pulley is a pulley that is not directly connected to a power source or used for power transmission. Instead, it is used to guide and redirect a belt or rope in a system. The idler pulley is typically positioned in such a way that it changes the direction of the belt or rope, adjusts tension, or provides support to ensure smooth operation.

Role in Mechanical Systems:

The primary role of an idler pulley in mechanical systems is to maintain proper tension and alignment of belts or ropes. It helps to redirect the path of the belt or rope, ensuring that it remains in the correct position and stays engaged with other pulleys or components.

Here are some specific roles and functions of idler pulleys:

1. Belt Tension:

An idler pulley can be used to adjust and maintain the tension in a belt or rope. By adding or removing an idler pulley or adjusting its position, the tension in the belt can be properly controlled. This is crucial for preventing slippage, ensuring efficient power transmission, and extending the lifespan of the belt.

2. Directional Change:

In some systems, an idler pulley is strategically placed to change the direction of the belt or rope. By guiding the belt along a different path, the idler pulley allows the belt to reach components that would otherwise be inaccessible or difficult to connect directly. This enables flexibility in designing mechanical systems and facilitates the proper functioning of various components.

3. Belt Alignment:

An idler pulley helps maintain proper alignment of belts or ropes. It ensures that the belt remains centered on the pulleys and does not deviate from its intended path. Proper alignment is vital for efficient power transmission, as misaligned belts can cause increased friction, wear, and loss of energy.

4. Load Distribution:

In systems with multiple belts or ropes, an idler pulley can be used to distribute the load evenly. By introducing an idler pulley between two driving pulleys, the load can be divided, reducing stress on individual components and improving overall system performance.

5. Noise and Vibration Reduction:

An idler pulley can help reduce noise and vibration in mechanical systems. By providing additional support and tension to belts or ropes, it minimizes excessive movement and vibration, resulting in quieter operation and increased stability.

Idler pulleys are commonly found in various applications, including automotive engines, HVAC systems, conveyor systems, and industrial machinery. Their role in maintaining tension, guiding belts, adjusting alignment, distributing load, and reducing noise makes them essential components in ensuring the smooth and efficient operation of mechanical systems.

editor by CX

2024-05-10