Product Description

What is a belt tensioner?

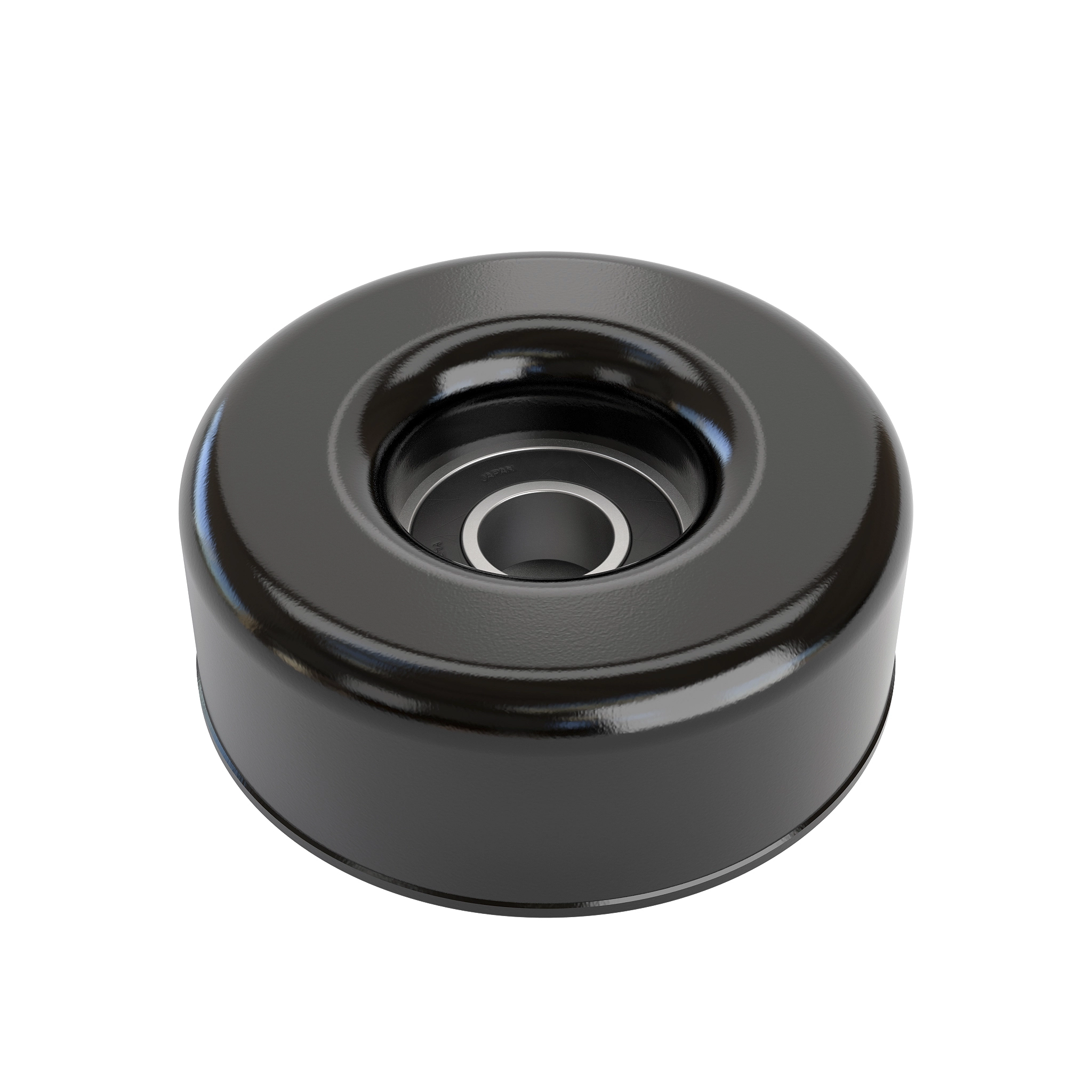

The tensioner is a belt tensioning device belonging to the automobile transmission system. It is mainly composed of a fixed housing, a tensioning arm, a wheel body, a torsion spring, a rolling bearing and a spring sleeve. The belt tensioner is used to adjust the tightness of the belt, reduce the vibration of the belt during operation and prevent the belt from slipping to a certain extent, ensuring the normal and stable operation of the transmission system. It is generally replaced together with the belt, idler and other cooperative accessories. The belt is a wearing part in automobile parts. When the belt is used for a long time, it is prone to wear. When the groove of the belt is worn deep and narrow, it will appear to be stretched. At this time, a hydraulic unit or damping needs to be performed through a tensioner. Spring, and the tensioner wheel can automatically adjust according to the degree of wear of the belt. Therefore, the belt tensioner wheel installed on the car can make the belt run more smoothly, reduce noise and prevent slipping.

The principle of belt tensioner:

The belt tensioner requires a certain amount of torque to maintain the proper tension of the belt during use and avoid belt slippage and elongation caused by aging or wear. When the belt tensioner is running, the belt can cause vibration in the tensioner, which will accelerate the wear of the belt and the tensioner. Therefore, in order to avoid this situation, we need to add a resistance mechanism to the tensioner. However, because the belt tensioner is affected by different parameters, its relationship with torque and resistance is complicated. The change in torque directly affects the change in resistance, and is the main factor affecting resistance. The parameters of the torsion spring are also the main factor affecting torque. Therefore, in order to better improve the resistance value of the belt tensioner, it is necessary to appropriately reduce the pitch diameter of the torsion spring.

The main function of the belt tensioner is to adjust the tightness of the timing belt, reduce the vibration of the belt during operation, prevent the belt from slipping and ensure the normal and stable operation of the transmission system. Although the belt tensioner pulley has powerful performance, its service life is short. Many car owners complain that the belt tensioner is broken before the belt is broken. When this happens, the timing belt and tensioner pulley should be replaced together. Therefore, HDAG tensioner suggest that under normal circumstances, the belt tensioner should be replaced every 3-5 years or about 80, PR21120-1 ; MP406.1308080-28 740.51-13 0571 0 740.11-13 0571 0 740.11-13 0571 0 ; 40624.1571571 5340.1308110.10 ; 21126-1 53104 0571 53157110 2 211261

2.Customize brand bag and box design AS REQUIRE+master carton

Notes: all master carton with woven bag to avoid broken during transit, offer pallets service if demand

Reference our belt tensioner pulley packing way,we have full experience to supply different brands all over the world:

Our HDAG belt tensioner and pulley machining and production workshops:

HDAG belt tensioner pulley pull push force and tensile testing, assemble Testing, full size tolerance testing:

I. We only do OEM, produce high precisional Auto belt tensioner, belt tensioner pulley, tensioner pulley, timing pulley, idler pulley, HALF SHAFT, WHEEL HUB BEARING, WHEEL BEARING, different with other factories

II.Quality guarantee: We promise to all of our old and new customers: ONE year guarantee or 50,000kms since B/L date, If we ship u wrong products or any quality problem, we will full compensation with free.

Customer visits

Contact Us

If you need high quality Auto belt tensioner, tensioner pulley, idler pulley, timing pulley, Wheel Bearing Hub bearing for passenger cars, or to be HDAG distributor or agent, please don’t hesitate to contact us.

Welcome contact us for sending interesting list by mail or Office ONE THREE NINE FIVE SEVEN SIX SIX SEVEN FIVE NINE SIX, THANKS /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Three Years |

|---|---|

| Warranty: | One Year |

| Type: | OEM Standard |

| Material: | St12 45# 40cr ADC12 Bearing Steel etc |

| Tolerance: | OEM Standard |

| Certification: | ISO/Ts16949 |

| Customization: |

Available

| Customized Request |

|---|

How do idler pulleys enhance the efficiency and longevity of machinery and equipment?

Idler pulleys play a crucial role in enhancing the efficiency and longevity of machinery and equipment in several ways:

1. Belt Tension and Alignment:

Idler pulleys help maintain proper tension and alignment of belts in belt-driven systems. By applying the right amount of tension, idler pulleys prevent belt slippage and ensure efficient power transmission. Proper alignment reduces wear on belts and other components, minimizing energy losses and extending the lifespan of the equipment.

2. Reduced Bearing Load:

Idler pulleys distribute the load on the belt, reducing the load on the bearings of other rotating components. This helps prevent premature bearing failure and extends the life of bearings, reducing maintenance requirements and downtime.

3. Vibration Damping:

Idler pulleys can absorb and dampen vibrations that occur during operation. By reducing vibrations, idler pulleys minimize stress on the belt and other components, improving overall system performance and reducing the risk of component failure.

4. Belt Span Length:

Idler pulleys enable longer belt spans, which can reduce the number of required pulleys and overall system complexity. Longer belt spans provide smoother power transmission, minimize the number of potential failure points, and improve overall system efficiency.

5. Load Distribution:

Idler pulleys help distribute the load evenly across the belt, ensuring that no single section of the belt is subjected to excessive stress. This balanced load distribution reduces the risk of belt stretching, premature wear, and failures, contributing to improved equipment longevity.

6. Belt Wrap Angle:

By adjusting the position and angle of idler pulleys, the wrap angle of the belt can be optimized. A larger wrap angle increases the grip between the belt and pulleys, improving power transmission efficiency and reducing the risk of slipping.

7. Tension Control:

Idler pulleys allow for convenient tension control in belt-driven systems. By adjusting the position or tension of the idler pulley, the tension on the belt can be fine-tuned to match the specific requirements of the machinery, optimizing performance and reducing wear.

Overall, idler pulleys contribute to the efficiency and longevity of machinery and equipment by ensuring proper belt tension, reducing bearing load, damping vibrations, enabling longer belt spans, distributing loads evenly, optimizing belt wrap angles, and providing tension control. By incorporating idler pulleys into belt-driven systems, manufacturers can improve system reliability, reduce maintenance costs, and extend the lifespan of their equipment.

What role do idler pulleys play in maintaining proper belt alignment?

Idler pulleys play a crucial role in maintaining proper belt alignment in mechanical systems. Here’s a detailed explanation of the role idler pulleys play in maintaining proper belt alignment:

Proper belt alignment refers to the correct positioning of the belt along the pulleys in a system. It ensures that the belt remains centered on the pulleys and follows its intended path without deviating or slipping off. Belt misalignment can lead to a range of issues, including increased friction, wear, noise, and reduced power transmission efficiency. Idler pulleys help address these alignment challenges and contribute to the smooth operation of the system.

1. Belt Tracking:

Idler pulleys guide the belt and help maintain its tracking along the pulleys. They are strategically positioned to ensure that the belt remains in the desired position and follows the correct path. By providing a reference point and support, idler pulleys prevent the belt from wandering or shifting laterally, which could otherwise cause misalignment.

2. Tension Adjustment:

Idler pulleys can be used to adjust and maintain the tension in the belt, which is crucial for proper alignment. By adding or removing idler pulleys or adjusting their position, the tension in the belt can be controlled. Proper tension ensures that the belt remains engaged with the pulleys and does not slack or become too tight, both of which can lead to misalignment.

3. Belt Support:

Idler pulleys provide support to the belt, helping to prevent sagging or excessive vibration. They act as additional contact points along the belt’s path and distribute the load, ensuring that the belt remains in its intended position. This support helps maintain the alignment of the belt, especially in applications where the belt spans long distances or encounters varying loads.

4. Load Distribution:

Idler pulleys contribute to load distribution across the belt. By introducing additional pulleys strategically, the load on the belt can be divided, reducing stress on individual components. This helps to minimize the risk of belt misalignment due to uneven loading or excessive strain. By distributing the load, idler pulleys promote uniform wear and ensure the longevity of the belt.

5. Vibration and Noise Reduction:

Idler pulleys play a role in reducing vibration and noise in mechanical systems. Misaligned belts can cause excessive vibration and noise due to uneven forces and increased friction. By maintaining proper alignment, idler pulleys help minimize these issues, resulting in quieter operation and increased system stability.

Overall, idler pulleys are essential components in maintaining proper belt alignment. Their role in guiding the belt, adjusting tension, providing support, distributing load, and reducing vibration ensures that the belt remains properly aligned, leading to improved efficiency, reduced wear, and extended belt life in mechanical systems.

What is an idler pulley, and what is its role in mechanical systems?

An idler pulley is a specific type of pulley that is used in mechanical systems. Here’s a detailed explanation of what an idler pulley is and its role in mechanical systems:

Definition:

An idler pulley is a pulley that is not directly connected to a power source or used for power transmission. Instead, it is used to guide and redirect a belt or rope in a system. The idler pulley is typically positioned in such a way that it changes the direction of the belt or rope, adjusts tension, or provides support to ensure smooth operation.

Role in Mechanical Systems:

The primary role of an idler pulley in mechanical systems is to maintain proper tension and alignment of belts or ropes. It helps to redirect the path of the belt or rope, ensuring that it remains in the correct position and stays engaged with other pulleys or components.

Here are some specific roles and functions of idler pulleys:

1. Belt Tension:

An idler pulley can be used to adjust and maintain the tension in a belt or rope. By adding or removing an idler pulley or adjusting its position, the tension in the belt can be properly controlled. This is crucial for preventing slippage, ensuring efficient power transmission, and extending the lifespan of the belt.

2. Directional Change:

In some systems, an idler pulley is strategically placed to change the direction of the belt or rope. By guiding the belt along a different path, the idler pulley allows the belt to reach components that would otherwise be inaccessible or difficult to connect directly. This enables flexibility in designing mechanical systems and facilitates the proper functioning of various components.

3. Belt Alignment:

An idler pulley helps maintain proper alignment of belts or ropes. It ensures that the belt remains centered on the pulleys and does not deviate from its intended path. Proper alignment is vital for efficient power transmission, as misaligned belts can cause increased friction, wear, and loss of energy.

4. Load Distribution:

In systems with multiple belts or ropes, an idler pulley can be used to distribute the load evenly. By introducing an idler pulley between two driving pulleys, the load can be divided, reducing stress on individual components and improving overall system performance.

5. Noise and Vibration Reduction:

An idler pulley can help reduce noise and vibration in mechanical systems. By providing additional support and tension to belts or ropes, it minimizes excessive movement and vibration, resulting in quieter operation and increased stability.

Idler pulleys are commonly found in various applications, including automotive engines, HVAC systems, conveyor systems, and industrial machinery. Their role in maintaining tension, guiding belts, adjusting alignment, distributing load, and reducing noise makes them essential components in ensuring the smooth and efficient operation of mechanical systems.

editor by CX

2024-04-12